Aluminum plates are useful in modern production because of their stability, durability, and flexibility in a variety of applications. These plates are well-known for their dimensional integrity and remarkable warping resistance, making them perfect for precision machining and other demanding applications. Their distinct properties make them an excellent alternative for businesses that require dependable, high-quality metal components, hence increasing manufacturing efficiency and product quality.

Understanding the Benefits of Cast Aluminum Plates

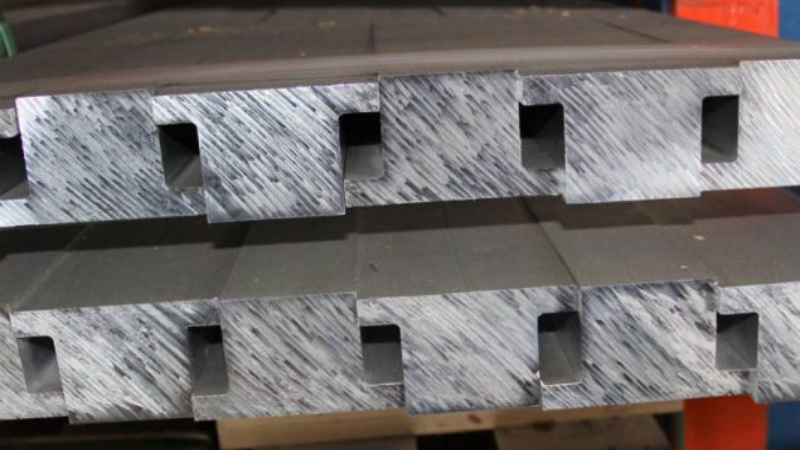

Aluminum plates stand out for their structural integrity and resistance to stress-induced deformation, making them excellent for applications that need exact measurements. Unlike many other metals, these plates are more stable due to the casting technique, which allows the material to cool slowly and naturally. This delayed cooling process decreases internal tensions, which can degrade the dimensional accuracy of machined items over time. Cast aluminum plate also have high thermal conductivity and corrosion resistance, which helps them last longer in a variety of situations. These qualities make them especially useful in environments where exposure to shifting temperatures or moisture would normally damage other materials. These plate’s durability and robustness enable them to accommodate a wide range of applications, making them an affordable choice for many high-precision production requirements.

Applications Across Various Industries

Cast aluminum’s versatility has made it a popular choice in businesses that require materials to meet demanding standards. Cast aluminum is also useful in the electronics industry because of its excellent thermal conductivity, which aids in heat dissipation. High-temperature electronics and machinery frequently use cast aluminum components because they effectively transfer and disperse heat, safeguarding the performance of sensitive electronic elements. This material’s heat management properties make it excellent for enclosures and cooling systems, where temperature regulation is critical to extending the lifespan and performance of electronics. The versatility of cast aluminum guarantees that these systems run with low downtime, increasing production and minimizing maintenance requirements.

Superior Machinability and Cost-Efficiency

Cast aluminum is easier to manufacture than other metals, resulting in faster manufacturing times and reduced prices. Its workability also reduces wear on cutting tools, lowering the frequency of tool replacement and contributing to long-term cost savings. For manufacturers, this means increased productivity and a competitive advantage in the marketplace because they can produce quality products more efficiently. This material sustainability is consistent with modern industry norms as more businesses seek environmentally friendly options in their manufacturing operations. Recycling cast aluminum saves energy and materials, resulting in a smaller environmental imprint and promoting sustainable production methods.

A Practical Solution for Today’s Manufacturing Needs

Cast aluminum plate have proven indispensable in many industries due to their remarkable durability, dimensional stability, and ease of machining. This material offers a durable solution that improves the quality and efficiency of production activities ranging from aerospace to electronics. Cast aluminum allows manufacturers to make components with great precision and performance, providing constant quality and reliability over time. As industries expand, the demand for dependable and adaptable materials such as cast aluminum grows, emphasizing its importance in fulfilling today’s demands for precision and durability in a competitive market.